Gateway MD2641U - USB and Shutdown Problems

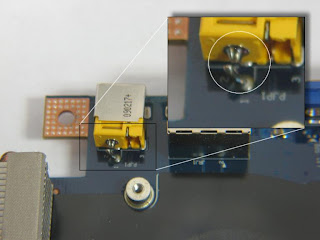

Gateway USB ports not read - This Gateway MD2614U would not recognize the USB ports or devices plugged into the unit. The problem was found to be manufacturer packaging mistake. Unit made by ACER in Taiwan has a large plastic cover on bottom of motherboard, but the surface mount resistors coils, and capacitors were not wave soldered well, so the bonds were not sticking to mobo, instead to the adhesive on the plastic. About 12-15 SMT parts were stuck to the plastic and had to be manually placed on the motherboard in their correct location for the USB ports to be read. The original reason this unit arrived was black screen/no video. Similar to the problem with the DV series using nVidia GPU though this was an ATI Chipset, the Southbridge and GPU were reflowed to assure solderballs were connecting under the chip itself. How did I find out this issue? Near the USB connectors the resistors were identified by their circuit designation, in this case it was the 300 series. (R353, C3